|

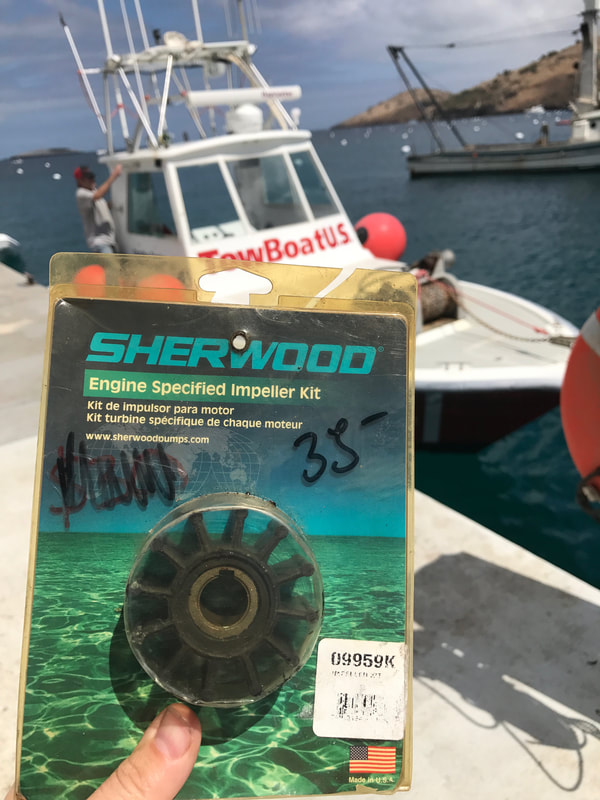

It finally happened. Kenutu created some real drama. We were having a gorgeous sail to Catalina, making excellent time with winds that let us point directly to our destination. We were chomping thru waves and admiring our perfect sail trim. At about 3pm, I kicked on the engine to motor in the final few miles so we could get moored before dark. At about 3:30 our engine temperature went to 250 and I was like, "Hey Mack...." We shut the engine off and Mack started doing some checks. He used the thermometer gun to see if the temperature gauge was reading correctly. He checked to make sure water was spitting out the back of the boat when the engine was on. He checked the coolant. The coolant was empty. Problem identified! Luckily we had some coolant on board. Mack refilled it, and we turned the engine back on and started motoring. That lasted about 20 minutes and then the engine started going from 200 to 250 again. The coolant was empty again and we didn't have anymore on board! We still had wind so we made our way slowly toward Two Harbors and kept trying to troubleshoot the problem, with the help of our smartphones. Mack remembered a scenario that he'd read about before where people are motor sailing heeled to one side for a long period and sea water doesn't make it in the intake to cool the engine. We had been having such a beautiful sail we didn't bother to flatten out the boat periodically to prevent that from happening. Problem identified! We figured we'd sail as upright as we could for as long as we could. The sun was going down, we were seven miles away from the harbor, and the wind was probably going to die down the closer we got to the island. Surprisingly, the only one who was being dramatic in all this was Kenutu. Mack and I were cool as cucumbers. No one was getting frustrated or annoyed, no one was bitching or complaining too much, and any time the Captain started to twitch toward something negative, I reminded him that we were safe and therefore we didn't have a real problem yet. We just had to be patient and prepare ourselves for a long waste of time. The sun went down, I bundled up in some warmies, and we kept on tacking our way to the harbor. The wind died so much so that a couple of times we tried to tack and failed because we couldn't get up enough speed. Finally we made it to the mouth of the harbor! The harbor master radioed us to see if we needed a mooring, we explained we'd reserved one five hours ago but our engine was overheating so we could only sail. "You're close enough now that I could give you a tow in if you need." Sweeter words have never been spoken. We dropped the sails and prepped for towing, which was a first for us. The plan was for him to get us to our mooring row, we'd engine for a couple minutes to get to the ball, and then he'd stick around to help us get tied up in case anything happened. I have never been more grateful to pay taxes in my life. He attached a line to our bow cleat and we were off, safely skirting the reef thanks to our boat angel. We got moored without any problems and got the engine shut off before it overheated again. We made dinner and went to sleep, and in the morning, with all the sun's glory and the mooring ball's security, we got to work. Mack started inspecting the entire cooling system. First was the raw water intake strainer. It can get clogged with sea debris and slow the flow of water to the engine. Ours was basically empty, but I scrubbed it with a toothbrush and gave it a fresh water rinse just to be nice. Next was the impeller. The impeller is this rubber wheel thing with sprocket arms that funnels the water in little boluses into the engine to cool it. To check it we had to unscrew some cap and pull it out. We put a bowl under where we were working so that we wouldn't lose any screws and have new problems to deal with. Sure enough the impeller was broken. Apparently the water lubricates the impeller as it spins, and when there's no water, things get really hot and the impeller can break to the point of being shredded. Once it's broken, it doesn't move water into the engine very effectively so it's gotta be replaced. Problem identified! We didn't have an extra impeller on board (lesson learned), but Two Harbors does have a seasonal boat shop. We dinghied to shore, grabbed a coffee, and tried to find a solution. They didn't have the impeller we needed, but they helped us identify the product number and informed us that our Boat US membership included vessel assist and parts delivery. God love em. We called Boat US and about an hour later another boat angel showed up with the perfect impeller, which I have a feeling was made about 14 years ago and has been on a dusty shelf in the shop of a possible lunatic for 10 years. But who cares! It was exactly what we needed! We felt like we were winning little victories all over the place. We got back to the boat and tried to put the new impeller in. And then we went crazy. We could not get the damn thing to slip into place. Mack texted Chris, the mechanic who'd given our Perkins an overhaul this spring, and he said to lube it up with some dish soap and fill the center with marine grease. We tried that but we still couldn't get it in. That little inlet up there is supposed to line up with something inside the housing, but getting that to happen is impossible considering you're literally putting it in blind. We even tried using our phone cameras to see what the hell was impeding our progress. How was this ever going in? Again we texted Chris for guidance. He told us there was a little metal piece in there that we could pull out, put in that little inlet, and then slide everything into place. Chris is also a boat angel. We'd bought some coolant when we were visiting the mechanic shop, so we refilled the coolant and continued to troubleshoot. We didn't see any leaks anywhere. We ran the engine for a while to charge the batteries and the temperature gauge stayed where it should! We even saw the soapy bubbles in the exhaust water, just like Chris said we would when he told us to lube the impeller with dish soap! Problem solved! Nope. Mack checked the coolant after running the engine and noticed it was almost gone again. We were befuddled. The guys at the diesel shop had told us it may be our radiator cap, but it seemed to fit just fine. Apparently if the radiator cap doesn't fit right the coolant can bubble out of the overflow tube and burn up on the hot engine, leaving no evidence of a problem. Mack engineered a clever way to test for loss, prevent it, and salvage some coolant. Basically he took the overflow tube and zip-tied it to our faucet over a cup in the sink. We could watch the tube from the cockpit to see if any anti-freeze was coming out. Anything that came out we could dump back in. Plus, gravity would keep the coolant from flowing out if it was a cap issue. We sailed home with the test in place, but the wind angels were on our side and we were able to sail all the way to the harbor. When Mack put on the engine, we watched for drips and monitored the temperature gauge and the engine temp with the thermometer gun. Everything ran as expected, and I think we got 2 drips total.

Problem identified! Again! Mack ordered a new radiator cap. And a back up. And maybe even another back up. He also installed a coolant collector for the overflow tube to drip into, so we can see if the cap fails us in the future. We still aren't sure what the original problem was -- the long heeling period, the empty coolant, the broken impeller, the ill-fitting radiator cap -- but ladies and gentlemen, whatever it was, PROBLEM SOLVED!

1 Comment

Don

3/1/2018 06:59:32 pm

Did any coolant get in the engine?

Reply

Leave a Reply. |

AuthorTwo people dumb enough to think anything is possible and smart enough to bumble their way into discoveries. Archives

September 2018

CategoriesMates |

RSS Feed

RSS Feed